The History of the Diesel Engine

Learn all about the history of the diesel engine, how diesel engines work, and the impact of the diesel engine on the world.

The diesel engine, a marvel of engineering, stands as a testament to human ingenuity and progress. Its story, spanning over a century, is one of innovation and adaptation, reshaping industries and transportation. As we explore the history of the diesel engine, we'll uncover how this technology has powered our past and continues to drive our present.

Throughout the 20th century, diesel engines became integral to various sectors, from transportation to industry. The energy crises of the 1970s underscored the importance of fuel-efficient technologies, propelling the adoption of diesel engines in vehicles beyond trucks and buses. This period also saw significant innovations aimed at reducing emissions and improving sustainability.

Today's diesel engines are marvels of modern engineering, benefiting from decades of technological advancements. They power a vast array of machinery and vehicles, contributing significantly to the global economy.

Join us as we delve into the rich history of the diesel engine, exploring its origins, developments, and future prospects.

Understanding Diesel Engines

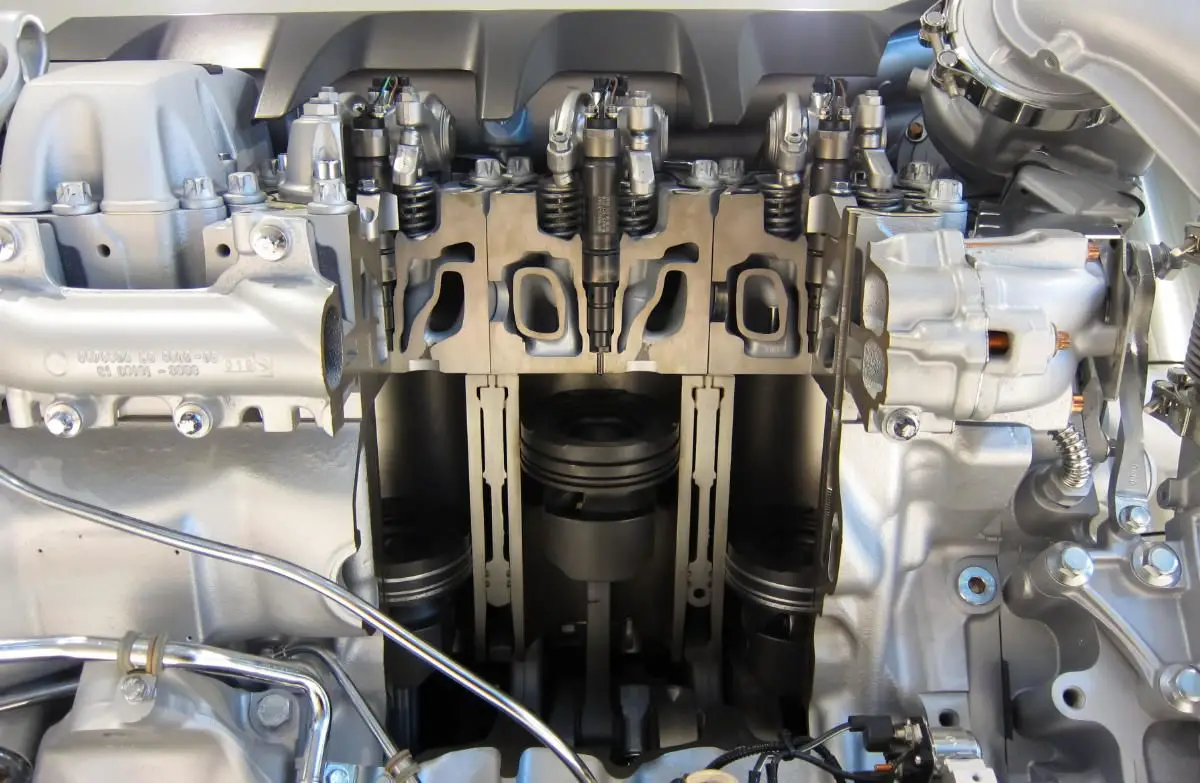

A diesel engine operates by igniting fuel using the heat generated from compressing air in the cylinder. Unlike gasoline engines, which use spark plugs for ignition, diesel engines rely on this compression-ignition process.

Diesel engines are notably efficient, often being up to twice as efficient as their gasoline counterparts, allowing vehicles to travel longer distances on the same amount of fuel. This characteristic efficiency has made them indispensable across various industries.

The fundamental principle behind diesel engines is the compression-ignition process. In a diesel engine, air is compressed to a much higher degree than in a gasoline engine, creating extremely high temperatures. When diesel fuel is injected into this hot, compressed air, it ignites spontaneously, eliminating the need for spark plugs. This high compression ratio is the key to the engine's efficiency, as it extracts more energy from the same amount of fuel compared to a gasoline engine.

This high efficiency is particularly advantageous for heavy-duty applications, where long operational hours and high fuel consumption are common. Diesel engines excel in scenarios requiring high torque and durability, such as in trucks, buses, and industrial machinery. Their robust design and ability to generate substantial torque at low speeds make them ideal for these demanding applications.

Modern diesel engines incorporate advanced technologies to further enhance their performance. Turbocharging is a prevalent feature, increasing the engine's efficiency and power output by forcing more air into the combustion chamber. This allows the engine to burn fuel more completely, resulting in higher efficiency and lower emissions. Direct fuel injection is another critical advancement, delivering precise amounts of fuel directly into the combustion chamber, optimizing combustion and reducing waste.

Despite their advantages, diesel engines have faced scrutiny for their environmental impact. Historically, they produce higher levels of nitrogen oxides and particulate matter compared to gasoline engines. However, technological advancements, such as selective catalytic reduction (SCR) and particulate filters, have significantly mitigated these emissions, making modern diesel engines cleaner and more sustainable.

The Birth of the Diesel Engine

The inception of the diesel engine can be traced back to the late 19th century, specifically to 1893 when Rudolf Diesel, a visionary German engineer, patented his groundbreaking design. Diesel aimed to engineer a power source that surpassed the efficiency of the steam engines prevalent at the time. His innovative approach involved compressing air to a high degree, leading to the ignition of fuel without the need for a spark, which is a fundamental difference from the way gasoline engines operate. This method resulted in significantly higher thermal efficiency, laying the foundation for a new era in engine technology.

Rudolf Diesel's early experiments were met with skepticism, but his determination paid off. By 1897, Diesel had created a working prototype that demonstrated the viability of his concept. This prototype engine was capable of converting more of the fuel's energy into mechanical work compared to existing engines, a milestone that heralded a significant leap in engine efficiency. Diesel's invention attracted attention and investment, facilitating further research and development.

The unique characteristics of diesel engines quickly found favor in various industries. The engines were robust and could run on a variety of fuels, including those of lower quality, making them highly versatile. This adaptability was particularly advantageous in industrial and marine applications where reliability and fuel efficiency were paramount. Early adopters recognized the potential of diesel engines to revolutionize sectors dependent on heavy machinery and long-distance transportation.

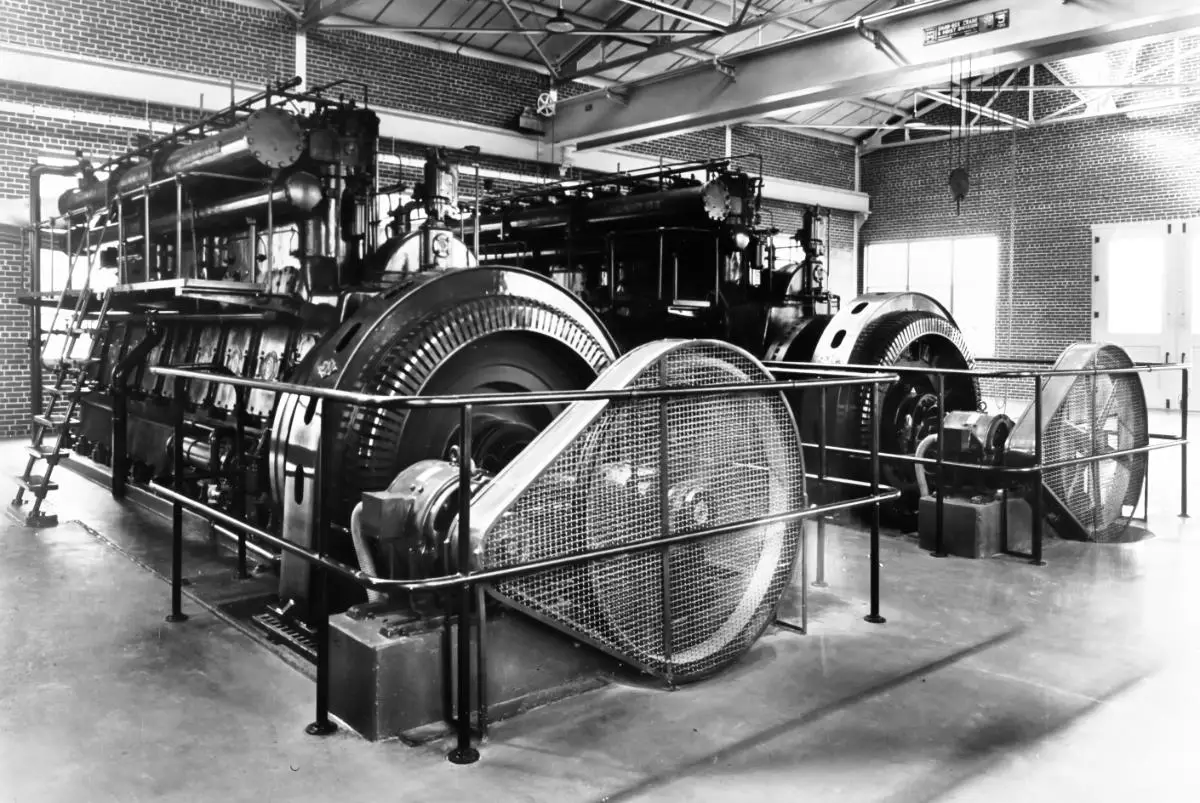

Initial applications of diesel engines were primarily in stationary settings, such as power generation and industrial machinery. These early engines were large and not yet suitable for mobile use. However, their success in stationary applications spurred further innovations. By the early 20th century, advancements in materials and engineering techniques enabled the development of smaller, more efficient diesel engines suitable for a broader range of uses.

Embed from Getty ImagesRudolf Diesel's vision extended beyond technical innovation; he foresaw the social and economic implications of his engine. He believed that the efficiency of diesel engines could democratize energy access, particularly benefiting developing regions by providing a reliable power source for industrial growth. This philosophy resonated with investors and industry leaders who saw the transformative potential of diesel technology.

As the 20th century progressed, the diesel engine continued to evolve. Innovations such as fuel injection systems and improved air compression techniques enhanced engine performance and efficiency. These advancements were critical in expanding the engine's applications to include transportation sectors like shipping and railways, where the superior fuel efficiency of diesel engines offered substantial operational cost savings.

Advancements in the Early 20th Century

The early 20th century witnessed significant enhancements in diesel technology. A major breakthrough occurred in 1925 when Alfred Büchi introduced turbocharging to diesel engines. This innovation increased engine efficiency by more than 40%, a significant leap for the time. The potential of diesel engines caught the attention of Adolphus Busch, who became the exclusive licensee in the United States and Canada. Busch invested what would now be $9 million to secure rights to this promising technology.

Diesel engines quickly found their place in ships and trains, revolutionizing the transportation industry with their unparalleled efficiency. Additionally, industrial applications began to expand, as diesel engines became integral to machinery, enabling enhanced productivity and economic growth. The introduction of turbocharging was pivotal. By forcing more air into the combustion chamber, it allowed for a more complete burn of the fuel, thus producing more power and reducing waste. This innovation made diesel engines an attractive option for sectors requiring high power output and efficiency.

Around the same period, the design and manufacturing processes for diesel engines also saw remarkable improvements. Metallurgical advances enabled the production of stronger and more heat-resistant engine components, which were essential for handling the high pressures and temperatures inherent in diesel operation. This resulted in more durable and reliable engines, further solidifying their industrial appeal.

The marine industry was among the first to embrace diesel technology. The robust and fuel-efficient nature of diesel engines made them ideally suited for powering large vessels. Ships equipped with diesel engines could travel longer distances without refueling, offering significant logistical and economic advantages. This extended range was particularly beneficial for cargo and passenger ships, contributing to more efficient maritime operations.

In the rail industry, diesel engines began to replace steam engines, marking a transformative period in train travel. Diesel locomotives offered several benefits over their steam counterparts, including higher efficiency, lower maintenance costs, and greater operational flexibility. The switch to diesel engines allowed railroads to streamline operations and reduce costs, which had a positive impact on the broader economy by making rail transport more viable and cost-effective.

The industrial sector also saw extensive adoption of diesel engines. Factories and other large-scale operations utilized diesel engines to power a variety of machinery, from generators to manufacturing equipment. The ability of diesel engines to run on various types of fuel, including lower-quality options, made them an attractive choice for industrial use. This versatility ensured that industries could maintain operations even when high-quality fuels were in short supply.

The advancements in diesel technology during the early 20th century were not confined to turbocharging and material improvements. There were also significant strides in fuel injection systems, which enhanced the efficiency and power output of diesel engines. Precise control of fuel injection allowed for better combustion and reduced emissions, addressing some of the environmental concerns associated with diesel engines.

These technological enhancements collectively broadened the range of applications for diesel engines and paved the way for their widespread adoption across multiple sectors. The early 20th century thus marked a period of rapid innovation and growth for diesel technology, setting the stage for future developments and solidifying the diesel engine's role in modern industry.

Innovations in the Post-War Era

The period following World War II marked a transformative phase for diesel engines, particularly in the automotive sector. By the 1960s, they had become the top source of power for the commercial trucking industry. This era saw significant technological advancements that enhanced both the efficiency and power output of diesel engines, solidifying their essential role in modern transportation.

Diesel engines in automobiles offered superior fuel economy and reliability compared to traditional gasoline vehicles. This shift was driven by a series of innovations aimed at optimizing engine performance and reducing operational costs. One of the most notable advancements was the refinement of fuel injection systems. Precise control of fuel delivery improved combustion efficiency and reduced emissions, making diesel engines more attractive for automotive applications.

During this time, diesel engines also began to see wider adoption in various commercial and industrial sectors. The improved durability and efficiency made them ideal for long-haul trucking, which benefited from reduced fuel consumption and lower maintenance costs. This shift had a profound impact on logistics and supply chains, enabling more cost-effective and reliable transportation of goods over long distances.

The post-war era also witnessed the introduction of new materials and manufacturing techniques that enhanced the robustness and longevity of diesel engines. Advances in metallurgy allowed for the production of engine components that could withstand higher pressures and temperatures, further improving the performance and reliability of diesel engines. These technological improvements were crucial in meeting the growing demands of various industries that relied on diesel-powered machinery.

In addition to automotive and industrial applications, diesel engines began to play a more significant role in the agricultural sector. Tractors and other farming equipment powered by diesel engines offered farmers increased power and efficiency, enabling more productive and cost-effective farming practices. This transition helped drive agricultural growth and contributed to the mechanization of farming processes.

Another critical development in the post-war era was the introduction of turbocharging technology to diesel engines. By forcing more air into the combustion chamber, turbochargers allowed for a more complete burn of the fuel, thereby increasing power output and reducing waste. This innovation was particularly beneficial for applications requiring high power and efficiency, such as in heavy-duty trucks and industrial machinery.

The marine industry also continued to adopt diesel technology during this period. Diesel engines provided the necessary power and fuel efficiency for large vessels, allowing ships to travel longer distances without the need for frequent refueling. This capability was especially advantageous for cargo and passenger ships, which benefited from the extended range and reduced operational costs associated with diesel engines.

The rail industry further embraced diesel technology, transitioning from steam to diesel locomotives. Diesel engines offered several advantages over steam engines, including higher efficiency, lower maintenance costs, and greater operational flexibility. The adoption of diesel locomotives revolutionized train travel and freight transport, making railroads more competitive and cost-effective.

Overall, the post-war era was characterized by a series of technological advancements that significantly enhanced the performance, efficiency, and versatility of diesel engines. These innovations played a crucial role in expanding the applications of diesel technology across various sectors, driving economic growth and transforming industries dependent on reliable and efficient power sources.

Diesel Engines in the Late 20th Century

As environmental concerns gained traction in the late 20th century, diesel engines faced new challenges due to their emissions. Nevertheless, advancements in fuel injection and turbocharging helped mitigate some environmental impacts. In 1997, diesel-powered passenger cars were not particularly popular in western Europe, making up only 22% of the market. However, this figure rose dramatically to over 50% by 2006. This surge was driven by improvements in diesel technology, which addressed efficiency and emissions concerns.

To tackle emissions, new technologies such as electronic control units (ECUs) and advanced fuel injection systems were integrated into diesel engines. These innovations allowed for more precise control over fuel delivery, optimizing combustion and reducing pollutants. The introduction of catalytic converters and particulate filters also played a crucial role in minimizing harmful emissions, making diesel engines more environmentally friendly.

Turbocharging technology, which had previously seen success in the marine and industrial sectors, became increasingly prevalent in automotive diesel engines. By forcing more air into the combustion chamber, turbochargers improved the efficiency and power output of these engines while simultaneously reducing fuel consumption and emissions. This technology made diesel engines a more attractive option for consumers concerned about both performance and environmental impact.

The late 20th century also saw significant regulatory changes aimed at reducing vehicle emissions. Governments worldwide implemented stricter emissions standards, compelling manufacturers to innovate and improve diesel engine technology. These regulations spurred the development of cleaner and more efficient engines, helping to mitigate some of the environmental concerns associated with diesel power.

In addition to regulatory pressure, consumer demand for more fuel-efficient vehicles contributed to the rise of diesel engines in the passenger car market. Diesel vehicles offered superior fuel economy compared to their gasoline counterparts, appealing to drivers looking to save on fuel costs. This economic advantage, combined with advancements in engine technology, led to a growing acceptance of diesel-powered cars.

Despite technological advancements, diesel engines still faced challenges related to public perception and environmental impact. Concerns over nitrogen oxide (NOx) emissions and particulate matter remained, prompting ongoing research and development to find solutions. The introduction of exhaust gas recirculation (EGR) systems and selective catalytic reduction (SCR) technology helped address some of these issues, further reducing harmful emissions from diesel engines.

The late 20th century marked a period of significant growth and innovation for diesel engine technology. As manufacturers and researchers continued to refine and improve these engines, they became more efficient, powerful, and environmentally friendly. This era set the stage for the continued evolution of diesel engines into the 21st century, as they adapted to meet the demands of a changing world.

In summary, the late 20th century was a transformative time for diesel engines. Through a combination of technological advancements, regulatory changes, and shifting consumer preferences, diesel engines evolved to become cleaner, more efficient, and more widely accepted in both the automotive and commercial sectors.

Contemporary Diesel Engine Technology

Modern diesel engines have undergone significant transformations to meet stricter environmental standards. Today, they are up to twice as efficient as gasoline engines, allowing for greater travel distances on the same amount of fuel. Diesel engines are not only used in commercial trucking and passenger vehicles but also serve as stand-alone generators across various industries. Stronger standards from the Environmental Protection Agency have led to the adoption of ultra-low sulfur diesel, resulting in cleaner-burning fuels.

In response to environmental demands, the diesel fuel industry is actively working on technologies to reduce emissions from older engines. One of the most critical components in modern diesel engines is the turbocharger. Diesel turbochargers play a crucial role by pumping more air into combustion chambers, which enhances power output and efficiency, particularly at high altitudes. Diesel turbochargers play a crucial role by pumping more air into combustion chambers, which enhances power output and efficiency, particularly at high altitudes.

As mentioned above, the integration of advanced electronic control units (ECUs) has revolutionized modern diesel engines. These units allow for more precise control over fuel injection, optimizing combustion and significantly reducing pollutants.

Additionally, the use of exhaust gas recirculation (EGR) systems has been instrumental in reducing nitrogen oxide (NOx) emissions, one of the primary pollutants associated with diesel engines. EGR systems work by recirculating a portion of the engine's exhaust gas back into the combustion chamber, thus lowering the combustion temperature and reducing NOx formation.

Selective catalytic reduction (SCR) technology is another vital development that has helped mitigate environmental impacts. SCR systems inject a urea-based solution into the exhaust stream, converting harmful NOx emissions into harmless nitrogen and water. This innovation has been particularly effective in heavy-duty diesel engines, making them compliant with stringent emission regulations.

Modern diesel engines also incorporate common rail injection systems, which allow for higher fuel pressure and more precise control over the injection process. This leads to better fuel atomization and more complete combustion, enhancing both efficiency and performance while reducing emissions.

The advancements in diesel engine technology have not only made them cleaner but also more versatile. Today, diesel engines are found in a wide range of applications, from powering industrial machinery and agricultural equipment to generating electricity in remote areas. Their ability to run on various fuel types, including biodiesel and synthetic fuels, adds to their adaptability and appeal.

The Future Prospects of Diesel Engines

As global industries strive to meet stringent environmental standards and reduce carbon footprints, diesel technology is evolving in tandem to remain relevant and competitive. Several emerging trends and technologies are set to define the next chapter for diesel engines.

One of the most promising advancements lies in the integration of alternative fuels. Biodiesel and synthetic fuels are gaining traction as they offer a cleaner combustion process compared to traditional diesel. Biodiesel, derived from renewable sources such as vegetable oils and animal fats, reduces greenhouse gas emissions and particulate matter.

Similarly, synthetic fuels, produced through chemical processes, can be tailored to burn more cleanly and efficiently. These alternatives not only lower environmental impact but also help diversify the energy sources for diesel engines.

Hybrid systems are another frontier for diesel technology. By combining diesel engines with electric powertrains, hybrid diesel vehicles can achieve superior fuel efficiency and reduced emissions. In urban environments where stop-and-go traffic is prevalent, hybrid systems can operate on electric power, switching to diesel for longer distances or when additional power is needed. This dual approach maximizes the strengths of both diesel and electric technologies, offering a balanced solution for reducing carbon emissions while maintaining performance.

The adoption of hydrogen technology also holds potential for transforming diesel engines. Hydrogen-diesel dual-fuel systems, where hydrogen is injected alongside diesel, can significantly reduce emissions. Hydrogen burns cleaner than diesel, producing only water vapor and nitrogen as byproducts. This technology could serve as a transitional solution, allowing existing diesel infrastructure to be utilized while reducing environmental impact.

Another perspective of the role of diesel engines in renewable energy integration is also worth noting. Diesel generators are often used in conjunction with solar or wind power to provide reliable backup power. This synergy between diesel and renewable energy can play a crucial role in the global shift toward sustainable energy systems.

Moreover, research into carbon capture and storage (CCS) technology offers another avenue for reducing the environmental footprint of diesel engines. By capturing carbon dioxide emissions directly from the exhaust and storing them underground or utilizing them in industrial processes, CCS can significantly mitigate the impact of diesel combustion.

Despite the advancements, the diesel industry faces ongoing challenges. Public perception and regulatory pressures continue to drive the need for cleaner and more efficient diesel engines. Continuous innovation and adaptation are essential for diesel technology to stay relevant in a rapidly changing energy landscape.

Final Thoughts

The history of diesel engines is a testament to human ingenuity and our drive for efficiency and reliability. Rudolf Diesel’s groundbreaking invention set the stage for a technological revolution, and over the years, diesel engines have proven essential across numerous sectors, from powering locomotives and ships to providing energy for industrial machinery and vehicles. The evolution of diesel technology has also paralleled shifts in global industry, with each advancement reflecting a growing emphasis on fuel efficiency, durability, and adaptability. As these engines became integral to transportation and commerce, they enabled industries and economies to expand at unprecedented rates.

Today, as the world faces new environmental and sustainability challenges, the diesel engine industry is evolving once again. With stricter emissions standards and the rise of alternative energy sources, diesel technology is adapting through innovations like cleaner combustion methods, improved fuel formulations, and hybrid systems. Although diesel engines may no longer dominate certain sectors, they continue to offer unique benefits that support a balanced energy mix. By investing in cleaner and more efficient designs, the diesel industry ensures that this venerable technology remains relevant in an era increasingly focused on a sustainable future.