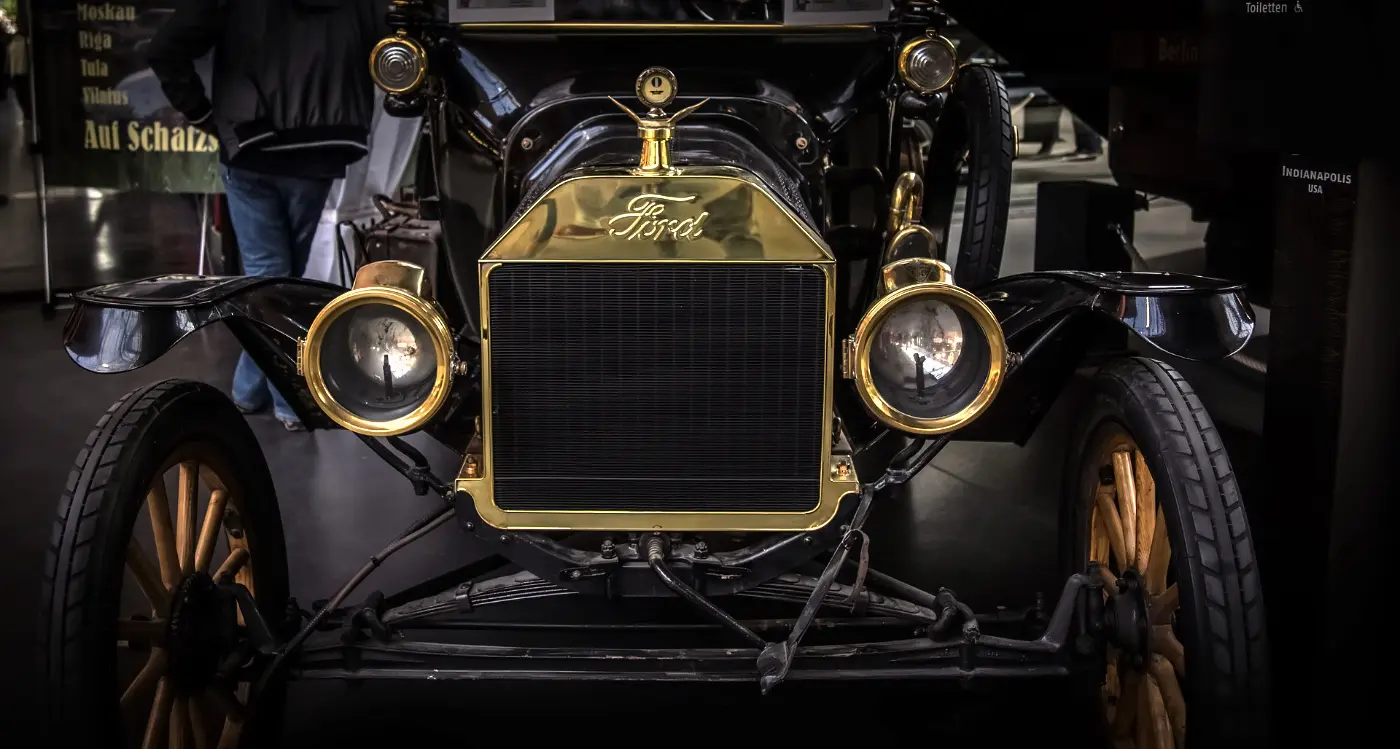

Ford Model T Engine: Everything You Need to Know

The Ford Model T engine revolutionized the automobile industry. The engine powered over 15 million Ford Model T cars and was known for its reliability and serviceability. Learn more about the engine here.

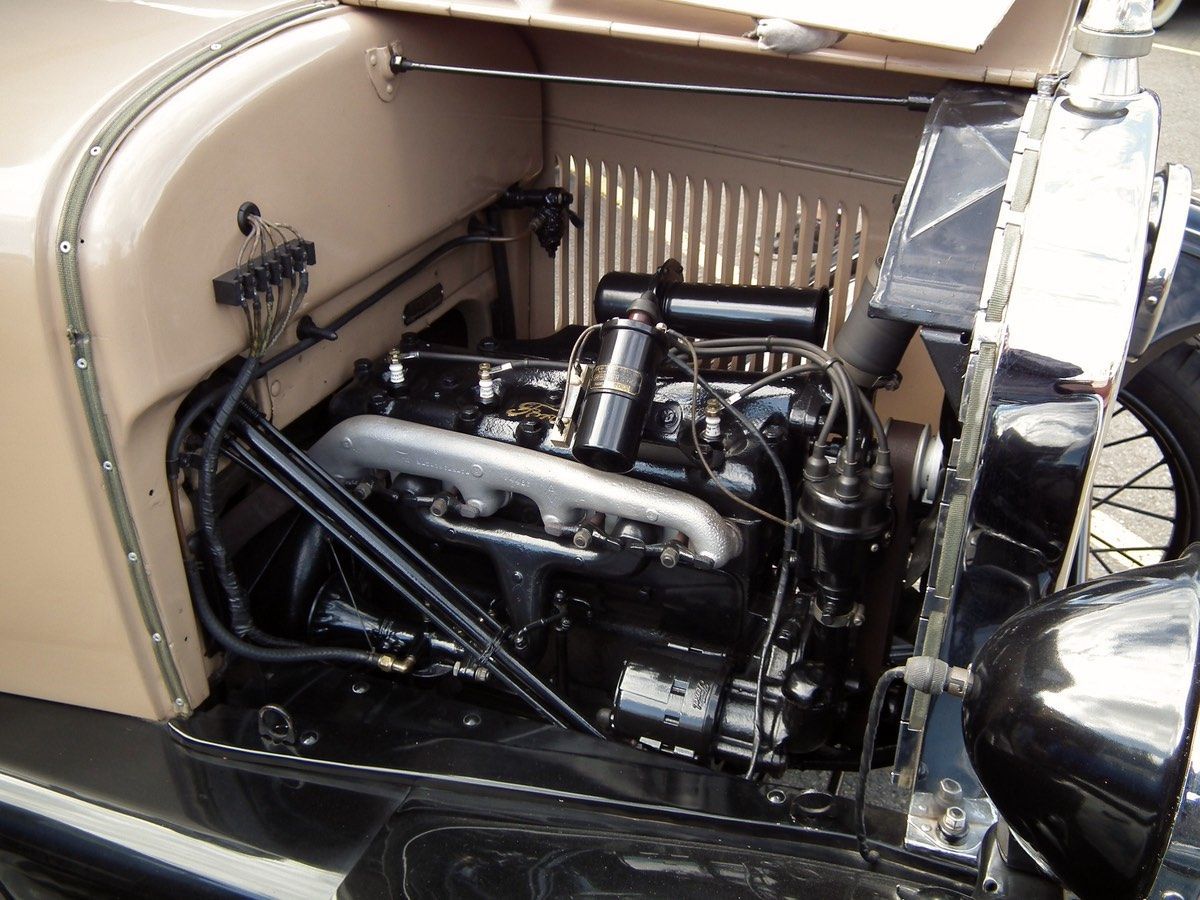

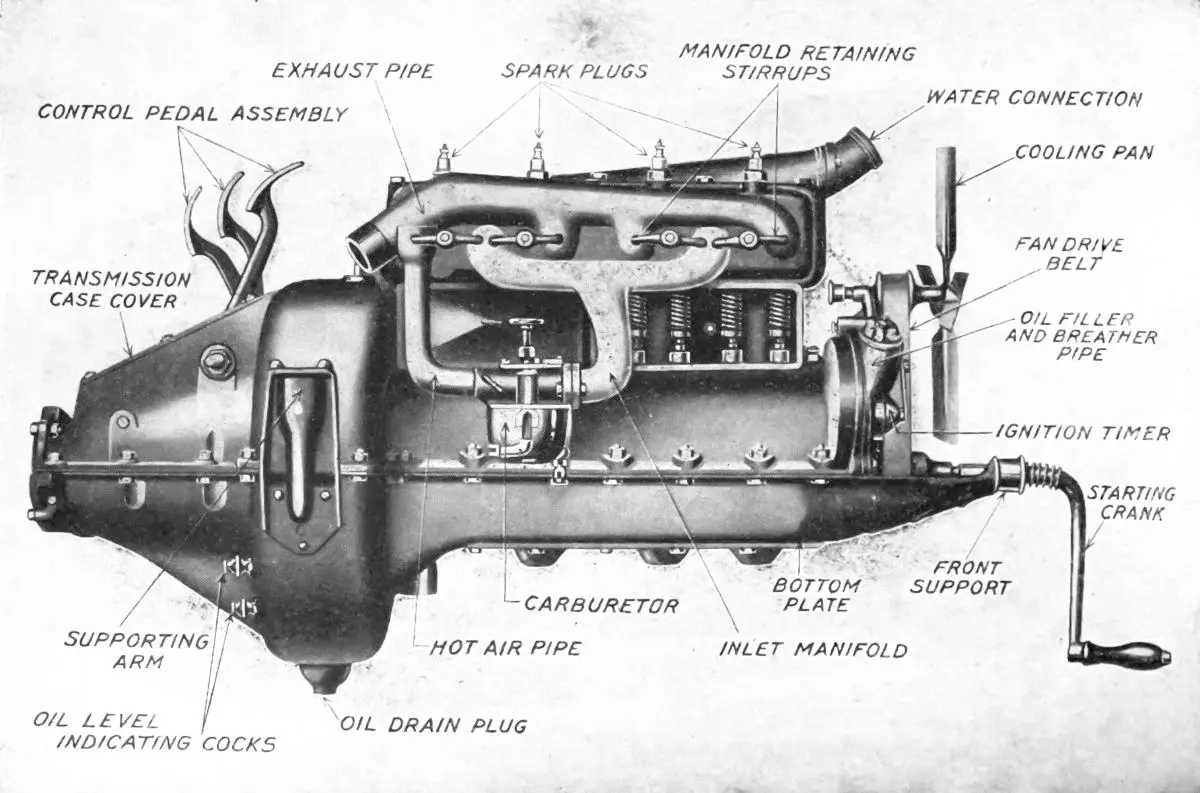

The Ford Model T engine was a 177 cubic inch (2.9 L) side-valve, reverse-flow cylinder head inline 4-cylinder engine. It produced 20 hp (14.9 kW) and offered a top speed of 45 mph (72 km/h).

It was produced for over 33 years and became one of the most successfully mass-produced engines in the world. Henry Ford designed it to be affordable, easy to operate and repair, and, above all, reliable. Let's take a look at the history and the specifications.

Where and how it all began

Henry Ford developed the Ford Model T engine over several years, with the initial successful testing of the motor on Christmas eve in 1893. The engine was only functional for 30 seconds, but that was deemed a massive success at the time and enough to pursue further testing and development.

Official development of the car and engine did not commence until 1907 when Ford and a small team started manufacturing the engine in a small Detroit factory on Piquette Avenue.

The engine was officially released and shipped to its first customer on October 1, 1908. The Ford Model T automobile was a self-starting vehicle featuring a 177 cubic inch (2.9 L) side-valve four-cylinder engine that produced 20 hp (14.9 kW) and offered a top speed of 42 mph (68 km/h).

Ford's engine was the first to have its engine block and the crankcase cast as a single unit and was the first engine designed to have a removable cylinder head for easy access.

Ford marketed the Model T to be affordable, simple to operate, and durable and sold for $850 in 1909, which was considered reasonable but markedly higher than the average American income could afford. Model T prices declined further over the following years.

The Model T became a huge success. By the early 1920s, more than half of the registered vehicles in the world were made by Ford. In 1927, Ford ceased production of the Model T Ford, having sold more than 15 million vehicles.

Technical specifications of the Ford Model T engine

The engine's bore was 3.75 inches (95.25 mm), and its stroke was four inches (101.6 mm). The Model T engine was intended to be a gasoline engine with a fuel consumption of around 13–21 mpg (miles per gallon) (18–11 L/100 km). The engine had one carburetor, a side-draft, single-venturi unit with choke and throttle valves controlled manually. In fact, the throttle was a hand lever, not a pedal, as in modern cars.

Initially, the Model T engine's carburetor had no fuel pump and relied on gravity feeding of the fuel supply. This caused issues when the vehicle was low on fuel, particularly when using the car on an accent (even mild hills), and Ford fitted the later Model T engines with an after-market fuel pump.

A market leader ahead of its time

The Ford Model T was a leader in engine design. At the time of production, it was one of the first cars to have a crankcase and engine block designed and manufactured as one single unit - also called a monobloc engine.

At the time, most engines used an aluminum crankcase with individual cast-iron cylinders that bolted on top to create a costly, intricate, and slightly flimsy system.

The Ford Model T monobloc casting, on the other hand, was easy to make, durable, and affordable. The one-piece detachable cylinder head used by the Model T engine was also much simpler to manufacture and service. The Model T engine block and head were made using cast iron which was cheaper and easy to handle. The L-head valvetrain mechanism was almost entirely enclosed, protecting it from grime and dust, which was another advantage. However, the monobloc, detachable-head engine design was largely responsible for enabling Ford to produce cars in record quantities at remarkably low prices.

The first Ford Model T automobiles came with a toolkit, and attention to design details implied that the vehicle could be easily repaired. Ford's monoblock engine design was not common during the early times of construction around 1908 but quickly proved itself successful for mass production. The cast iron cylinder head was designed to be easily removable, allowing for easy access to replace and repair valves and cylinders.

Manufacturing of the Ford Model T engine

The Model T engine was produced continuously from 1908 until 1941, amounting to precisely 12,000 days of production, making it one of the longest engine production runs in history. Ford used the engine in passenger vehicles from 1908 until 1927 and kept making them until 1941 for consumer, industrial, military, and marine markets.

The Model T engine was one of the first mass-produced components used. Ford Motor Company quickly paved the way for the mass-production techniques that revolutionized the automotive industry forever.

The existing factory at Piquette Avenue quickly ran out of expansion options, limiting productivity. So in 1910, Ford opened a 60-acre factory in Highland Park to churn out Model Ts, and in 1914 the assembly line could complete an assembly of a Model T Ford in just 93 minutes. Later expansions added more room to the factory, reaching 3 million square feet (278.709 square meters) of floor space.

The Model T engine, chassis, and other components were designed and manufactured on the Ford Motor Company's moving assembly line at Ford's revolutionary Highland Park Plant. Throughout production, the engine design and specifications remained almost entirely unchanged.

Ford's engine design was robust and designed for simplicity. It could also run on multiple fuel types, such as gasoline, kerosene, or ethanol. Ford developed this "multifuel" capability to appeal to farmers who, at the time, were allowed to create their own fuel from excess corn.

Marketing and sales of the Model T Ford and engine

Ford engaged in several high-profile publicity stunts to prove the Model T engine's capabilities. The Model T was initially tested on public roads by Henry Ford himself, who drove the vehicle on a hunting trip from Detroit to Wisconsin and northern Michigan.

The Model T also performed other tasks to wow audiences, including climbing the stairs of the Tennessee State Capitol (in Nashville, Tennesee) and climbing to the summit (14,115 feet) of Pikes Peak.

It wasn't only in America that Ford engaged in publicity stunts to attract customers. In 1911, a Scottish Ford car dealer set a challenge for his son to drive a Model T to the summit of Ben Nevis, the highest mountain of the British Isles. The feat was completed over five days, seeing the vehicle drive over rocks, challenging terrain, and even snow.

The publicity stunt was a huge success and led to over 14,000 Model T Ford vehicles sold in Scotland and England. It also marked the last time Ford needed a publicity stunt to sell his cars in Britain.

Summary

Ford revolutionized the automobile industry with the engine he and his team manufactured for over 33 years. The Model T engine was used in over 15 million Model T's worldwide. It was well known for being a sturdy and robust design that remained reliable, making it go down in history forever.

Also read: