Do Trains Have Anti-Lock Braking Systems?

Are you wondering whether anti-lock braking systems are used in trains? Learn all about what brakes trains use.

Trains are a method of transportation that have been around for hundreds of years, but the history behind their designs in locomotion and braking is often misunderstood. Do trains have anti-lock braking systems, and how do they work?

Trains do not have traditional anti-lock braking systems largely due to a lack of practicality. Some trains, however, do feature decelostats, which serve a similar purpose of allowing wheel rotation momentarily and reapplying the brakes.

The braking systems of trains have been developed and changed drastically since the locomotive was first invented in 1802, and the rest of this article will dive into the fascinating history of trains and how they’ve evolved over the years.

Do Trains Have Anti-Lock Braking Systems?

Anti-lock braking systems (ABS) are used in land vehicles, motorcycles, trucks, busses, and even aircraft to prevent the wheels from locking up while braking. Doing so allows the tract to maintain contact with the road surface and affords the driver more autonomy over the vehicle’s movements.

Over the years, ABS has become a standard in many transit vehicles, but they have never been used in trains. It might surprise you that, barring a few tweaks, the compressed air brake system used in most freight trains has remained virtually unchanged since their inception in the early 1800s.

Why Don’t Trains Have ABS?

Trains are massive beasts of burden that tow millions of pounds behind them, and the main reason that they haven’t adjusted their braking system in the last 200 years is quite simply because air pressurized brakes work reliably. For massive freight trains, ABS is a technology not worth investing in.

After all, ABS generally increases the stopping distance of a vehicle by allowing the wheels to spin momentarily before the brakes are reapplied. In practice, this allows the driver to better control where they are going at the cost of a greater stop distance.

For trains, of course, the ability to control where they are going is virtually pointless since they’re on a track and don’t need to manuever at all. Reliability is the key, and compressed air brakes are as reliable as they come.

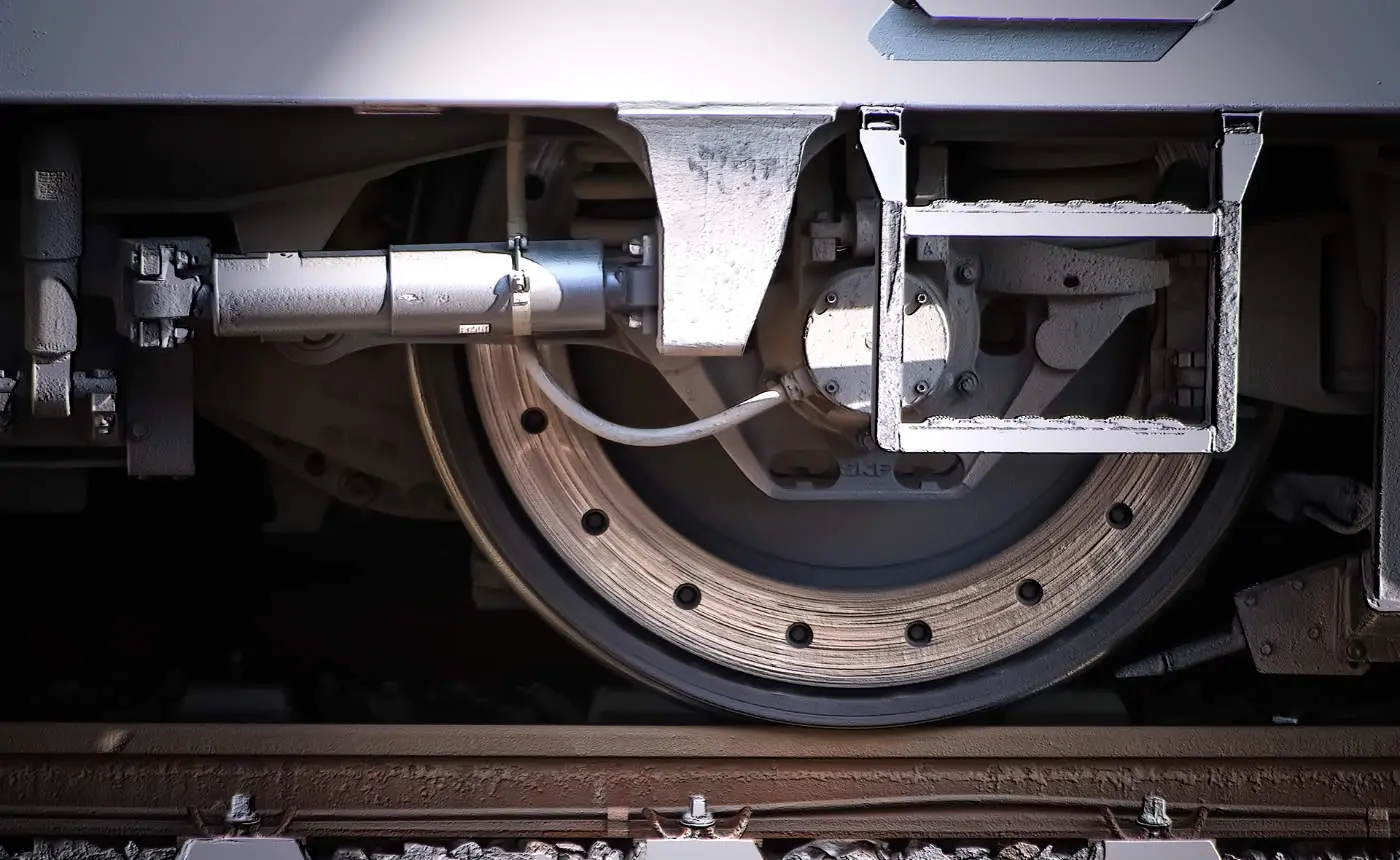

In the US, freight trains rely on two different brake systems: the brake pipe and the brake cylinder. Both are air pressurized between 70 and 100psi depending on the company and region.

When the conductor initiates the brakes, all of the air in the brake clamps is expelled, using friction to stop the wheels and bring the train to a halt.

Once initiated, the brake pipe cannot be repressurized automatically, ensuring that the train comes to a complete stop. It’s old, but effective. The train will stop because there is no other alternative to stopping once the chamber is depressurized.

The reason these air-pressurized brake systems have and will likely continue to be used in trains is down to their effectiveness. When carrying a couple hundred tons of weight towing cars, it’s more important to come to a guaranteed complete stop rather than getting the slight benefit in slowing speed of 15% that ABS offers.

It can, however, be argued that a lot of trains have fallen behind modern technology, with many control systems feeling out of date and sluggish compared to the rapid advances that have been made in the fields of automotive technology and aviation.

There is a certain hesitancy that comes with changing something so fundamental to a train’s safety features, and the industry seems to operate by the old saying, “If it ain’t broke, don’t fit it.”

Regenerative Braking in Trains

One advance in train braking system technology that is of note is the use of regenerative braking in trains, leading to a substantial reduction in emissions.

Regenerative braking is an energy recovery mechanism that converts friction energy from braking into usable energy for the system.

In other words, trains equipped with regenerative braking get a little kickback of energy every time they come to a stop. The effects may be minimal per brake, but they certainly add up when paired with the right technology.

When it comes to commuter trains, suburban trains, and, in a few cases, freight trains, regenerative braking has seen lots of use. If you think about it, commuter trains that are constantly stopping are burning a lot of energy that could be put to use, and regenerative braking just makes sense.

On commuter trains, emissions are reduced anywhere from 8 to 17%, while suburban network trains see a reduction of up to 30%.

The Pursuit of ABS in Train Systems

The general rule that ABS takes longer to stop holds true in the majority cases, but the theoretical “perfect” ABS system is actually faster than just hard clamping the brakes to stop.

That’s because when the coefficient of friction the wheel provides against the road is overcome, the wheel will skid, resulting in a reduction of deceleration. As such, for the perfect stopping power, a wheel should incorporate ABS braking exactly when the wheel is about to skid, allowing it to move and preventing skidding.

In trains, overbraking is especially damaging, since it can not only reduce brake performance, but can also damage the wheels.

Decelostats are a system designed for trains that releases the brakes momentarily if skidding is detected, reducing stopping distances by allowing for the most efficient braking. These systems have seen some use since the 2010s, although the technology has been around for quite some time.

Once the decelostat system detects deceleration of wheel rotation, the system manipulates the brake valves to allow the wheels to rotate and subsequently be clamped again to continue braking.

Final Thoughts

There are a lot of reasons that anti-lock braking systems aren’t used in trains, but it’s mainly down to the lack of function ABS has in controlling movement on a railroad track, although some types of trains feature decelostats, which serve a similar function by allowing wheel rotation to prevent skidding and optimize deceleration.

In other types of trains, compressed air brakes see more use thanks in large part to their reliability in stopping.